Main Features of SkyERP MES Production Management Software

The solution combines the MES operating system integrated into the Odoo ERP system. Therefore, MES is operated synchronously with other Odoo modules such as Purchasing, Logistics, Inventory, Financial Accounting, Sales, Human Resources, and Equipment Maintenance in a unified system.

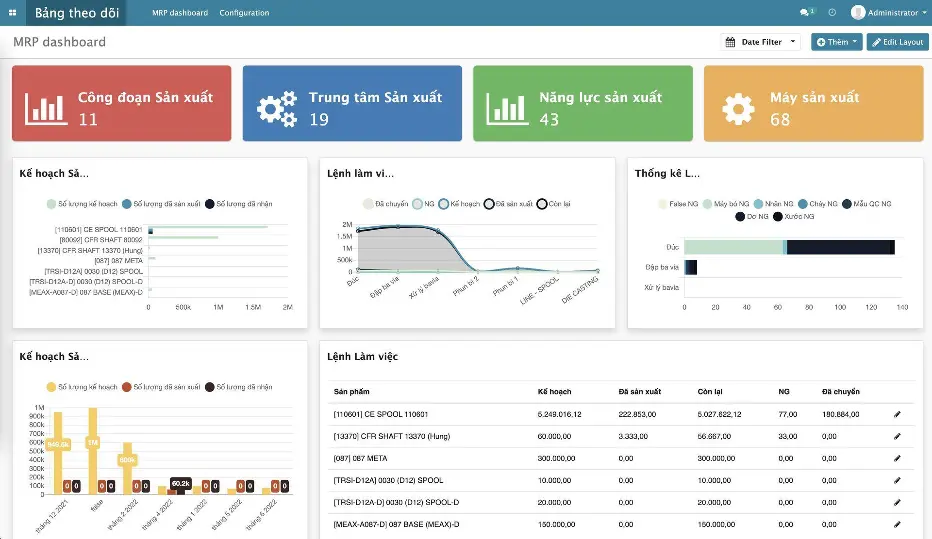

MES Dashboard

(MES dashboard)

Customizable dashboard can be configured according to the user, allowing powerful access control

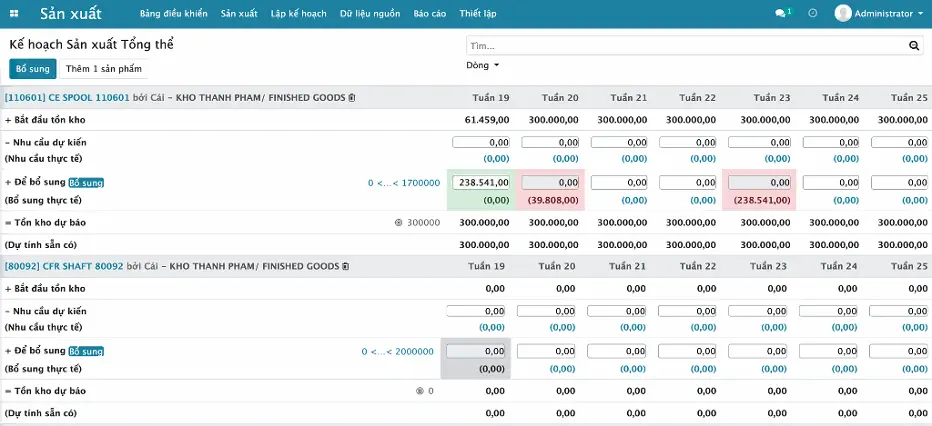

Overall Production Planning

(Overall Production Planning)

(Automatically calculate and forecast future inventory quantities based on current inventory, purchase orders, sales orders, and existing production orders)

Automatically suggest procurement (purchase, production, warehouse transfer) when material shortages occur based on replenishment rules or minimum inventory levels.

Automatically generate production orders or Purchase Orders (PO) based on supply rules.

Automatic Material Supply Proposal

(Above: Automatic material supply recommendation system)

(The system automatically calculates future inventory based on current inventory and procurement, production, and sales forecasts)

Based on the supply rules set for each product, the system can automatically create production orders, purchase requisitions, or purchase orders to ensure the desired inventory level.

Settings are flexibly configured for each product.

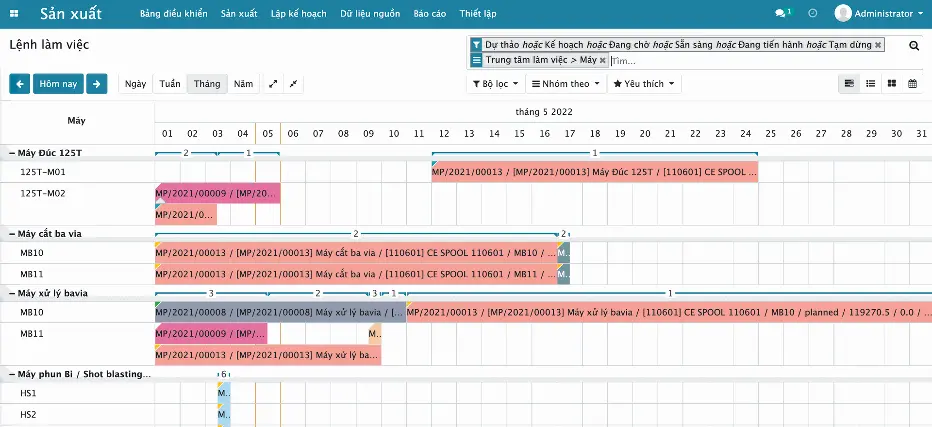

Overall Work Orders for Each Stage

(Image above: Detailed assignment of specific work orders to each stage)

Manage production visually and in detail at each stage in real-time.

The production planner can simultaneously optimize multiple production plans based on priority or adjust them using intuitive drag-and-drop operations.

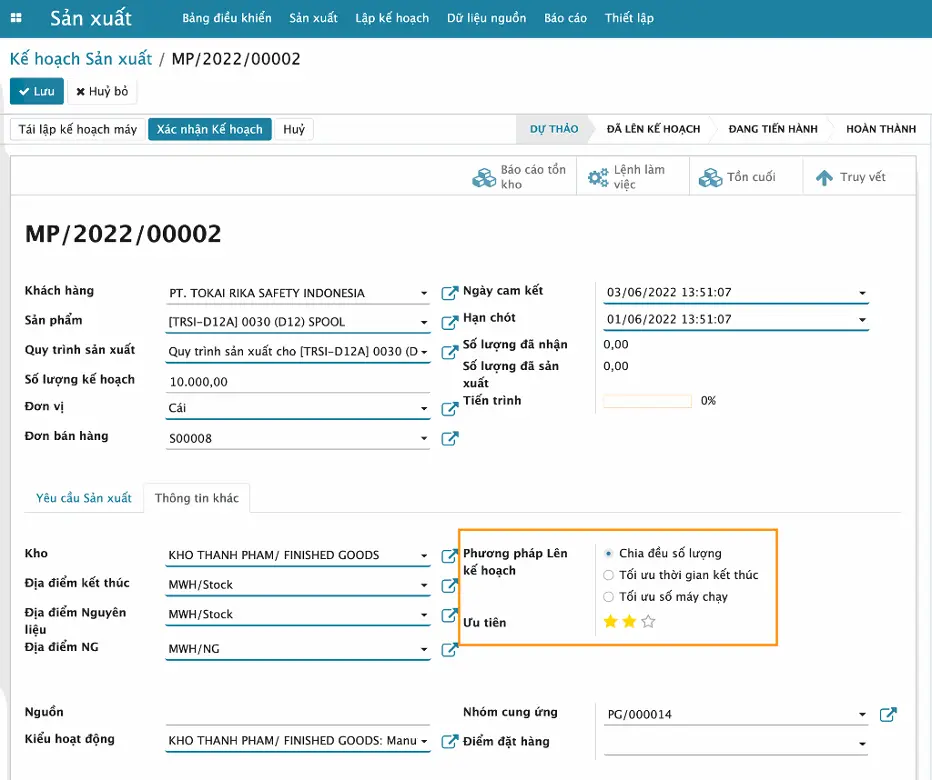

Automatic Production Resource Calculation and Forecasting

(Automatically calculate production resources)

Based on the production capacity of each machine, each stage for each product, and existing work orders, the MES software automatically calculates and optimizes the work order for each machine.

Receive delays warnings during planning before production begins.

SkyERP MES has three optimization mechanisms:

- Equal distribution of quantity

- Optimize finish time

- Optimize the number of running machines

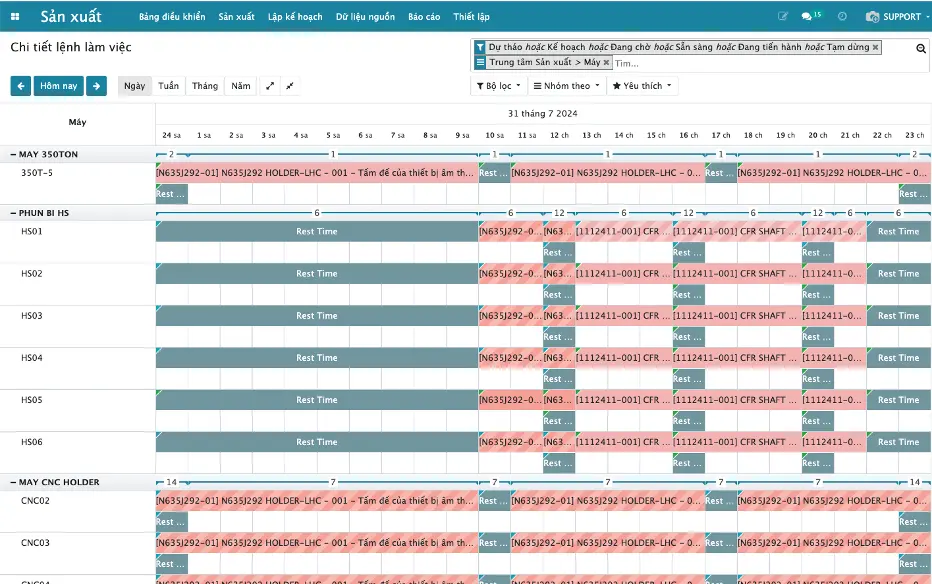

Work Schedule for Each Machine

(The work order is automatically calculated for each machine, accurate to the minute, including rest times)

The production management software’s machine management feature allows the automatic creation of work schedules for each machine and synchronizes them with the schedules of other machines.

Machine managers can see work orders assigned to their machine organized by status in an intuitive manner.

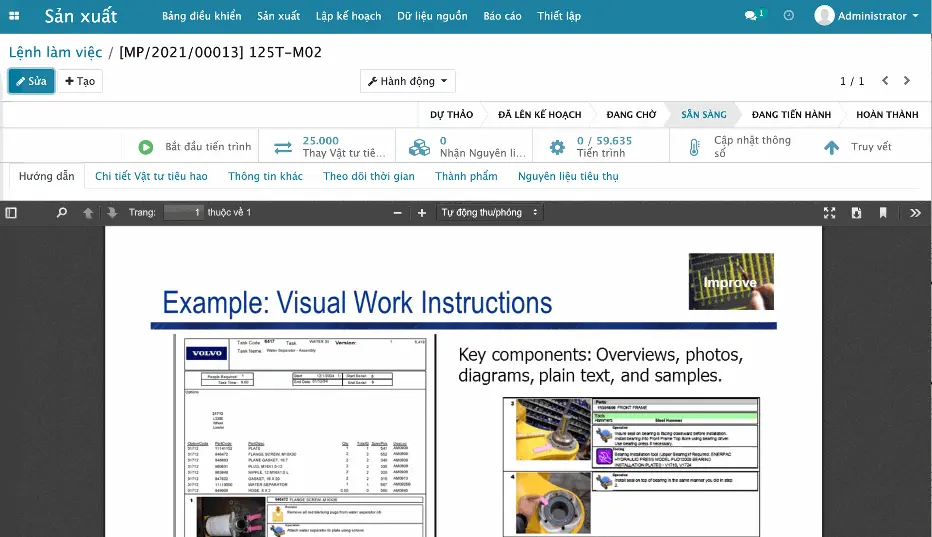

Operation Instructions for Each Stage

(Operation instructions at each stage)

The OneMRP production management system supports the use of display screens for monitoring at each stage. Users can:

- View operation instructions for the stage

- Record activities such as receiving materials, recording production progress, updating machine parameters, and transferring materials to the next stage

- View all information related to the work order

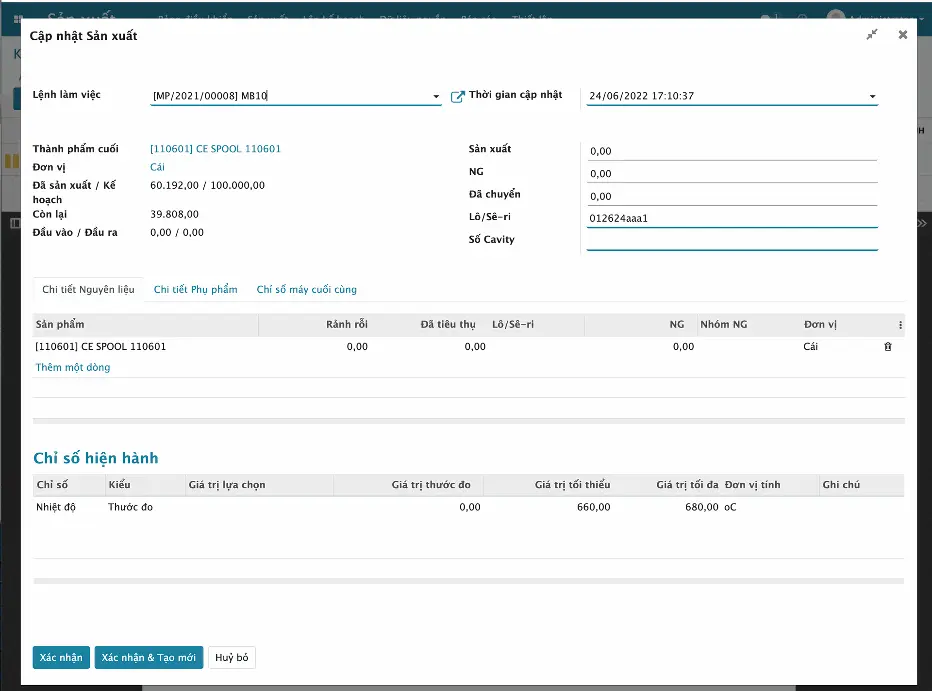

Production Progress Updates

(The system automatically updates production progress)

The MES production operating system (SkyMES) allows direct production progress updates at each machine through touch screens:

- Update the quantity produced

- Update the number of defective goods by defect type

- Update semi-finished goods and finished goods transferred to the next stage

- Update material consumption

- Update machine parameters

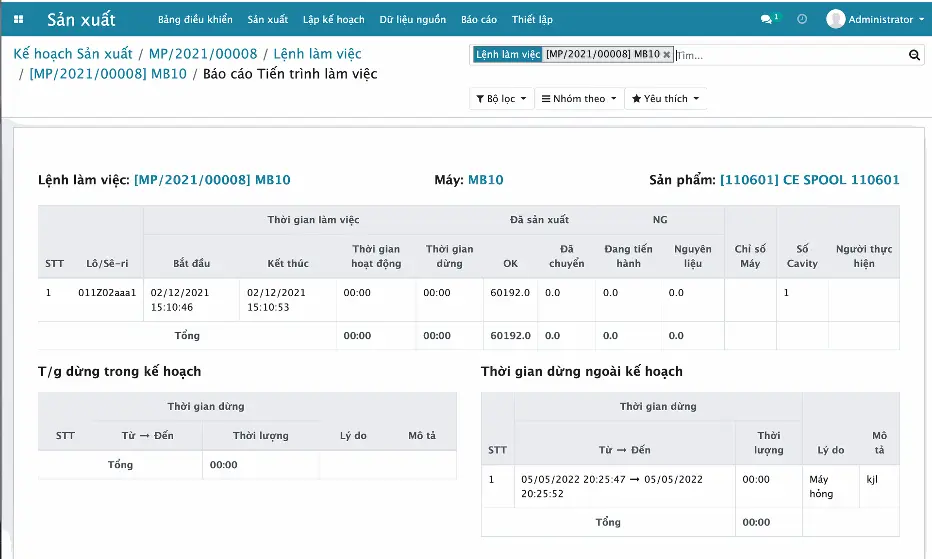

Production Reporting

(Easily generate various production reports)

The MES production operating system offers diverse reports that allow analysis from multiple perspectives:

- Inventory reports at each stage by production order

- Dynamic defect (NG) reports for multi-dimensional analysis

- Detailed traceability reports

- Detailed production reports for a single production order

- Detailed production reports for the entire factory

- Production cost reports

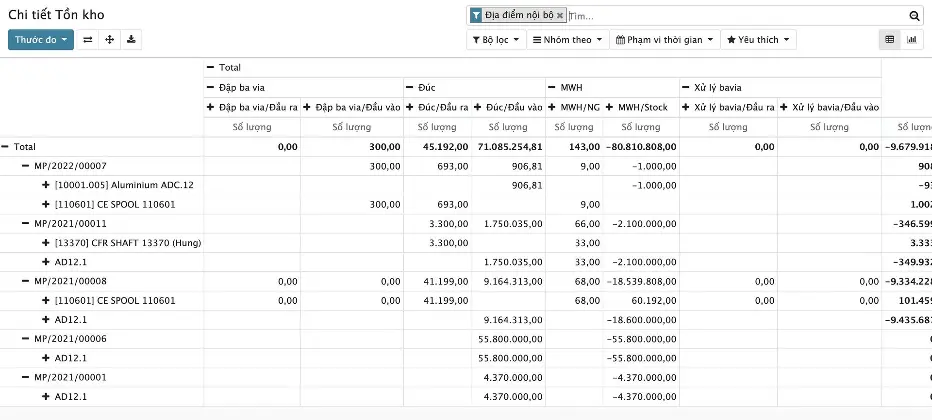

Inventory Management at Each Stage

(The system manages detailed inventory at each stage)

The MES production operating system allows for detailed inventory management at each stage:

- Manage inventory of raw materials, semi-finished goods, and finished products before and after each stage

- Manage the transfer of materials, semi-finished goods, and finished products from one stage to the next

- Manage defective goods

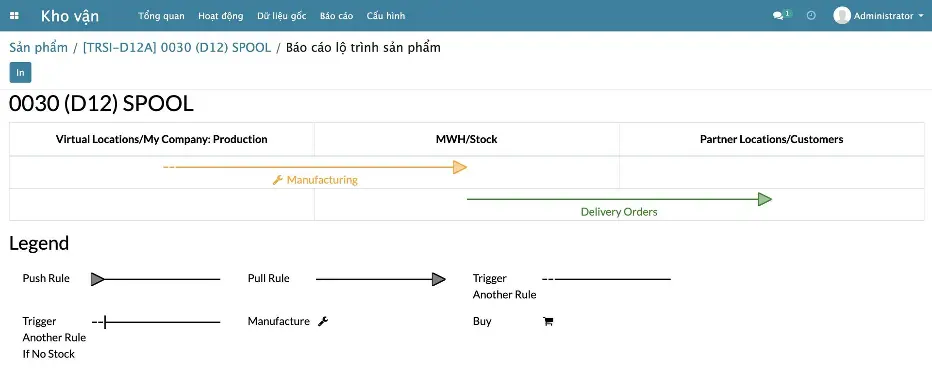

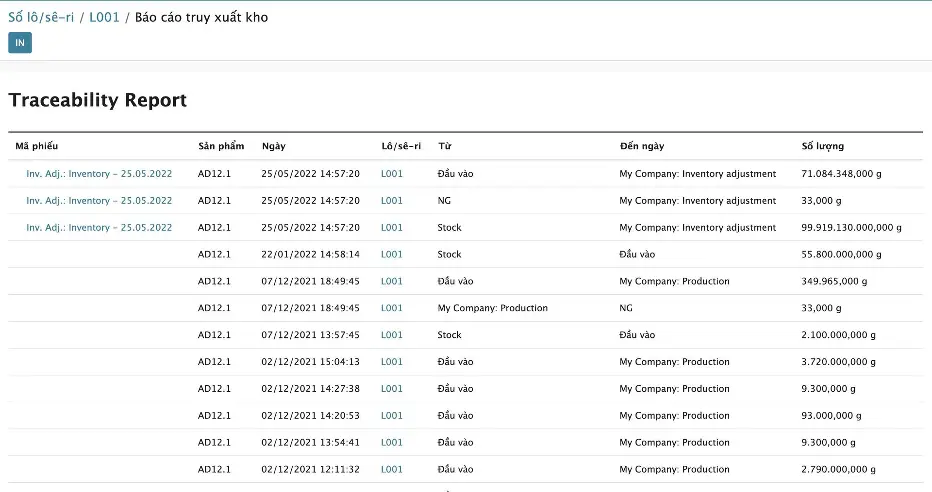

Traceability

(The system helps track the origin of materials and goods)

The MES production operating system allows tracking of all warehouse changes from purchasing to box entry to sales orders and material movement within each production order.

Track serial numbers or batch numbers from anywhere in your supply chain.

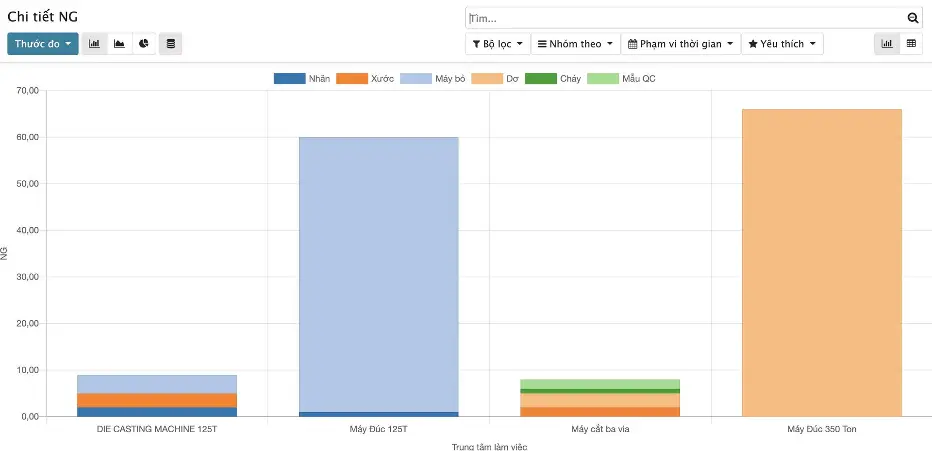

Defective Goods (NG) Management

(The system allows managing defective goods in each production stage)

The ERP production management software (OneMRP) allows easy management of defective goods in each production stage.

Defect statistics reports by stage, time, machine, defect type, and cause.

Preventive actions to reduce NG.

Track and analyze NG over time.

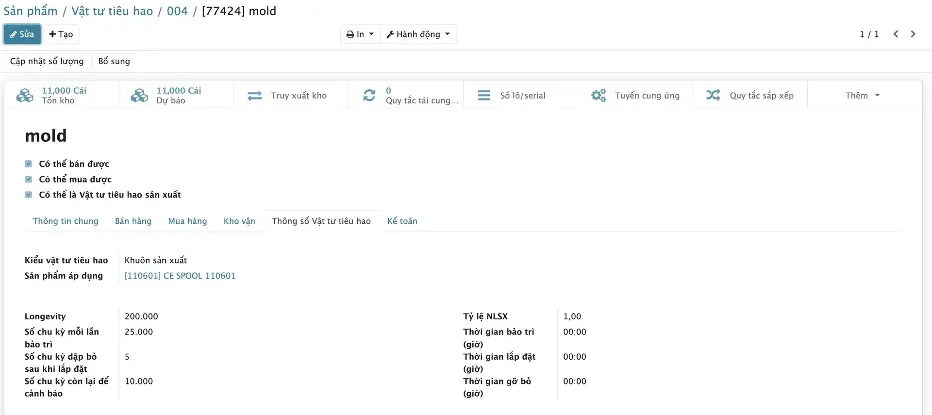

Consumable Materials Management

(The system helps manage consumable materials)

Consumable materials are materials used in the production stage that are consumed but not part of the raw materials. Examples include molds during casting, cutting blades during cutting, etc.

Consumable materials can be tracked in detail by serial number; for example, each casting mold can be tracked for the number of cycles used, remaining lifespan, number of maintenance operations performed, and predict the next maintenance time.

Track the number of cycles that consumable materials have been used.

Automatically schedule and plan consumable material maintenance, with maintenance warnings when due.

Automatically schedule consumable material replacement when its lifespan ends, and provide replacement warnings when the replacement time arrives.

Production Cost Calculation

The MES production operating system allows precise calculation of production costs, including direct costs and monthly allocated overhead costs, and automatic calculation of average cost of goods sold, including complex allocations.

Accurately estimate direct production costs, including material, machine, and labor costs immediately after setting up the BOM and production process.

Precisely track actual production costs for each production order based on actual material consumption, real-time material usage, and actual NG

More about Manufacturing Execution system (SkyMES)